Friday, September 30, 2016

Friday

A few days ago we tried the finalized code and nothing seemed to work. Today we found out that the problem was that we were missing a "while(1 == 1)" phrase before the segment that included the drive system. Now one side of the robot is able to drive but the other side has a physical problem that keeps it from moving. One of the axles are crooked and that is keeping the wheels from turning. Once that is fixed that should be all we need to do before finishing up our robot's wiring and testing our program.

Thursday, September 29, 2016

Wednesday, September 28, 2016

Wednesday Post

Today we started working out how the pole lifting system will work. We want to make sure that we have a functional lift since lifting the robot above a certain point earns you 12 points. That can be a real game changer and it is one of our main focuses for scoring. We are also finishing up the final form of the program that includes both autonomous and remote control. Our port-splitter arrived so we are now able to use all of the motors that we need for the drive system.

Monday, September 26, 2016

Absent

Today we had a magnet assembly to go to so we did not have a chance to work on our robot. However, Parker came by after school and tested our lifting system and found that it was working. Good job Parker. juan did a help

Friday, September 23, 2016

New Grasp Design

We have decided to revert to our other design option for our grasping mechanism. Since we had multiple issues with our design, even with the various changes we made to it, we are going with the sweeping design, but with a variation. Instead of using a single motor attached to a large gear > small gear > medium gear, we are going with two motors connected to a small gear > large gear. The code for each motor will run opposite of each other, causing the two metal pieces to move inward and pinch the object.

OLD DESIGN - New one uses two motors in a

different style but with the same rotation and plate

idea

Wednesday, September 21, 2016

Change of Plans

After the assembling the robot, the team realized that the claw is a bit too big and clunky. It is highly unlikely that the robot will be capable of lifting itself. Plus, the way the claw moves feels awkward and not very smooth. At minimum contraction, the arm does not meet the 18 inch requirement. It is too long.

Monday, September 19, 2016

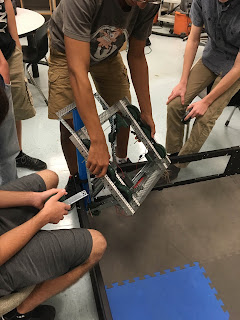

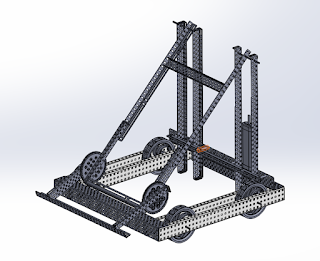

Building Week 4

Today, rather than build our robot from the ground up, we have elected to build each component individually and then piece them together. The drive system is almost complete, the arm is attached to the base, and the claw is close to being ready. The code for remote control mode and autonomous mode are both, for the most part, complete and ready for testing. Once the robot is assembled all we will need to do is test the code, make any needed adjustments, combine the separate parts of the program, and we should be good to go. Solidworks is also almost completed. Also, we have added blue LED lights to our cart for maximum swag points.

Friday, September 16, 2016

Thursday, September 15, 2016

Wednesday, September 14, 2016

Building Week 2

Wednesday - We have completed the chassis and horizontal sliding hand completely and are now working on the connections of the chassis to the arm and the arm to the hand.

Once that is complete we plan to connect all motors to the micro-controller and test the code we have been working on while constructing the robot.

Friday, September 9, 2016

Building Week 1

This past week we began our construction of the robot we designed. The chassis has been built and the horizontal sliding arms are being started. The chassis hold our four wheel, four motor design, geared for maximum speed. The horizontal slide or "claw" of the arm will consist of an L shaped hand on both sides that run in opposite directions to a minimum point, which is designed for best fit of both the star and the cube.

Subscribe to:

Posts (Atom)